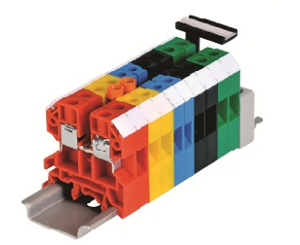

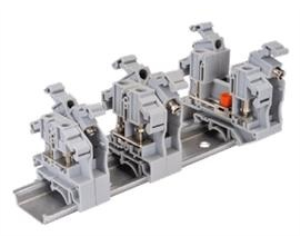

Universal (TS35mm & TS32mm)DIN Rail Mounted Feed Through Terminals in Polyamide 66 Housing offers the complete range suitable for all control and power application. The proven screw clamp & spring clamp design offers high contact force and is easy to use. The range covers terminals for conductor sizes from 0.5 sq mm to 95 sq mm for screw clamp and 0.5 sq mm to 16 sq mm for spring clamp. The special foot design provides the slot for easy mounting and removal of a single terminal from the stack, using a screwdriver.

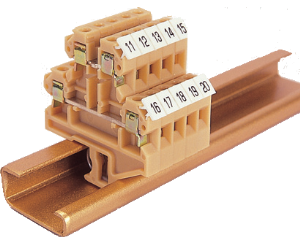

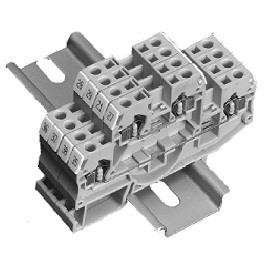

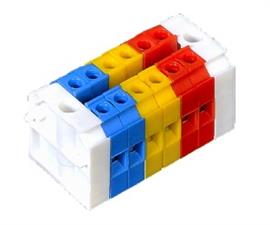

Multi Level Terminals are the perfect solution where space is a constraint and high density wiring is needed. The compact design of these Terminals with 6 mm thickness allows double wiring density and reducing the total number of terminal blocks to half. KUDD4 terminal is specially recommended as its upper level is offset laterally by half of the terminal block pitch. This offers better accessibility to the lower connection screws and better visibility of the lower marking labels. KU2D4 terminal blocks with internally shorted versions are suitable for one input and three outputs. elmex three level terminal blocks can be used for high-density wiring and for wiring special equipments such as proximity sensors. DUSD4 has a special link attached to the middle and lower level to facilitate the interconnection between adjacent terminal blocks, DU3D4 and DUSD4. The negative and positive circuits can be easily bridged together and then connected to a power source with DU3D4 terminal.

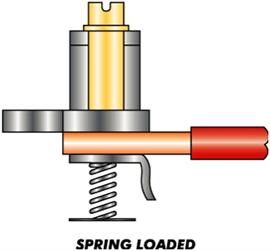

Vibrations adversely affect terminal connection, causing loosening of conductors and consequent overheating of terminal blocks. elmex Terminal Blocks are therefore designed to be inherently resistant to vibrations in normal applications. However, high vibrations can arise due to vibration affected installation sites, such as installations in and around mines, proximity to heavy machine shop,forging/ die casting shops, cement/steel plants machinery, textile machines and so on. Special designs for high vibration applications are also preferred in some Power Projects, Power Distribution Centers, Motor Control Centers and Relay Control Panels. depending on proximity of vibration generating equipment. elmex Standard Screw Clamp design, with compression springs, provided under the clamp, offer a reliable solution for high vibration applications of Terminal Blocks. These are called "SPRING LOADED" terminal blocks. FEED THROUGH TYPE: KST 4UWS, KST 6WS, KULT 4, KULT 6, KULT 1 DISCONNECTING TYPES: KULTD 4WS, KULTD 6 The spring is assembled under compression, so that it engages firmly with the contact clamp. For inserting the conductor, clamping screws should be unscrewed and pressed, which results into pushing down the contact clamp against spring action and creates space for conductor insertion below the current bar. When the screw is tightened with specified tightening torque,the clamping part moves to cause gripping of conductor with current bar, as with normal clamping process, but in case of spring loaded design, the conductor is gripped with additional clamping force exerted by the compression spring from below the clamping part. Special design of the current bar with a recess is available to anchor the hook bladed cable lug, in the current bar. This provision creates conductor locking within terminal block once it is clamped, so that it cannot be pulled out accidentally. This design is presently available in types KULT 1, 4, 6 and KULTD 4, 6.

These are the same group of Stud Type Terminals, however, they have their own hinged individual protective covers, which are lifted up for connection and closed down after conductors are connected. This design makes them totally finger-safe, enhancing total safety. As an innovative solution, elmex has developed Stud Terminals OAT 2.5 and OAT 6. These terminals are provided with Hinged Covers within which the nuts remain captive. When the covers are opened up, carrying the captive nuts, the threaded bolts of the terminals are ready to receive the conductor prepared using Ring / Fork type lug crimped with the conductor. When the covers are closed the captive nut positions itself on the threaded bolt. The nuts are then tightened with a screw-driver, to establish the connections. The covers fully shroud the live metal parts and the insulated lug in the conductor clamping area, ensuring safety against electric shock hazards. Since the nuts are captive in the hinged covers, (i.e. No need to open them up), this type of construction facilitates quick and convenient way of making connections.

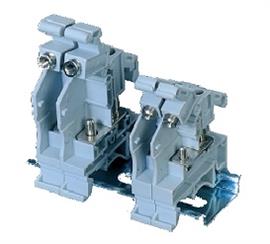

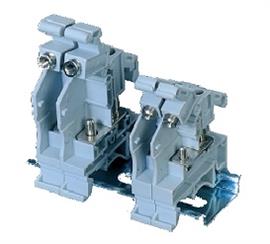

elmex offers a wide variety of Power / Bus-Bar / High Current Terminals suitable for all types of cables (solid, stranded, with fork type and ring type lugs) both in Polyamide 66 and Melamine Housing. In the Feed Through Range, Terminal types KUT25, 35, 50 and 95, with respective rated currents 101, 125, 150 and 232 Amps are available for connecting solid and stranded conductors. Power (Bus-Bar) Type terminal range covers DPBB50, 70 and 120, rated upto 269 Amps, for fork/ring type lugs, bolted to the current-bar of the terminal block. Protection and Safety For increased creepage distance and safety against accidental contact, partition plates / barrier plates are assembled along with the terminal block. Protective transparent covers are assembled at the slots provided on the barrier plates. This provisions make the assembly fully safe, while simultaneously offering open design of terminals for connection fork / ring lugged cables.

elmex offers a new design type SPT in which hinged covers are provided over the cable termination points. Cables with fork or ring lugs are connected by nuts to the terminal after lifting hinged covers which are closed after the connection is completed. These are Finger-safe Terminals by design, not requiring covers or barrier plates, for safety or protection. Their housing is Polyamide 66 and currently available with 35 sq mm and 70 sq mm connection capacity, and with rated currents of 140 Amps and 192 Amps respectively. Hinged covers are available in various colours as required optionally.

elmex 'U' Series Terminal Blocks are based on Modular Type design with all Brass parts for special applications. The proven screw-clamp design offers high contact force. The special design of the clamp makes it possible to terminate 0.2 sq mm conductor on the lower side. All metal parts are made of high conductivity brass. The housing is made of Polyamide 66. The feed through terminal blocks are available to accommodate conductor sizes from 0.2 sq mm to 10 sq mm. elmex Twin Terminal Blocks solve the problem of power distribution by accommodating two separate cable connection points on the load side. elmex Double Level Terminal Blocks offer an easy solution to space problem. The special feature of providing offset between lower and upper decks allow better accessibility to the lower level screws and visibility of labels.

elmex Multi Level Terminals are the perfect solution where space is a constraint and high density wiring is needed. The compact design of these Terminals with 6 mm thickness allows double wiring density and reducing the total number of terminal blocks to half. elmex three level terminal blocks can be used for high-density wiring and for wiring special equipments such as proximity sensors. elmex 8-level terminal block type DS8L offers very good wiring density particularly for marshaling applications where large number of wires are to be terminated and space is a constraint. Screwless multi-level terminal block wire termination is by spring clamp mechanism. Spring clamps are made using special grade austenitic stainless steel material having very good spring properties, high fatigue strength, high tensile strength and better resistance to corrosion effects.

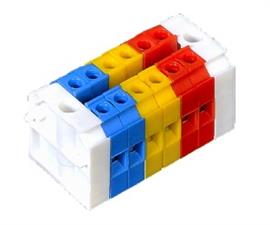

The Panel Mounted terminals of elmex range are so designed as to fit on any panel / surface. The terminals are stackable and can be fixed on the surface with the help of fixing screws at the end.

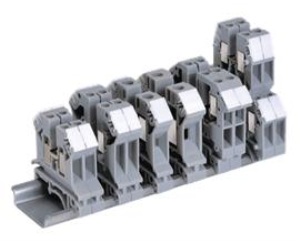

elmex Universal (TS32mm)DIN Rail Mounted Feed Through Terminals in Polyamide 66 Housing offers the complete range suitable for all control and power application. The proven spring clamp design offers high contact force and is easy to use. The range covers terminals for conductor sizes from 0.5 sq mm to 16 sq mm for spring clamp. The special foot design provides the slot for easy mounting and removal of a single terminal from the stack, using a screwdriver.

The Panel Mounted terminals of elmex range are so designed as to fit on any panel / surface. The terminals are stackable and can be fixed on the surface with the help of fixing screws at the end.

elmex Multi Level Terminals are the perfect solution where space is a constraint and high density wiring is needed. The compact design of these Terminals with 6 mm thickness allows double wiring density and reducing the total number of terminal blocks to half. elmex three level terminal blocks can be used for high-density wiring and for wiring special equipments such as proximity sensors. DUSD4 has a special link attached to the middle and lower level to facilitate the interconnection between adjacent terminal blocks, DU3D4 and DUSD4. The negative and positive circuits can be easily bridged together and then connected to a power source with DU3D4 terminal.